How 3D Printers Can Give Robots a Soft Touch

Softening Robotics: Transformative Advances Through 3D Printing

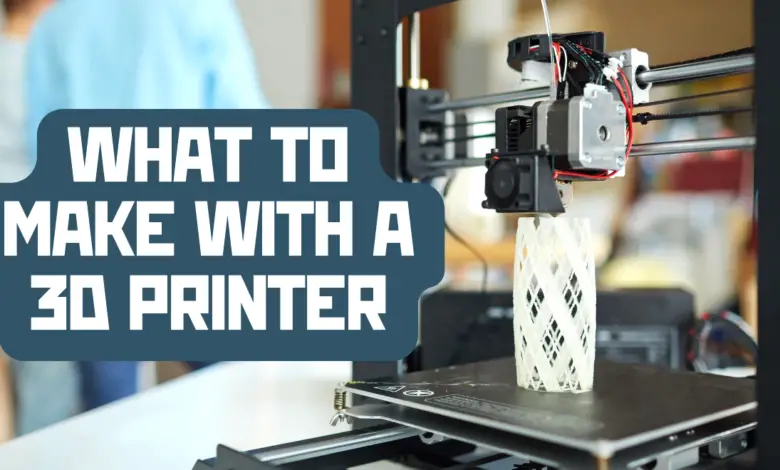

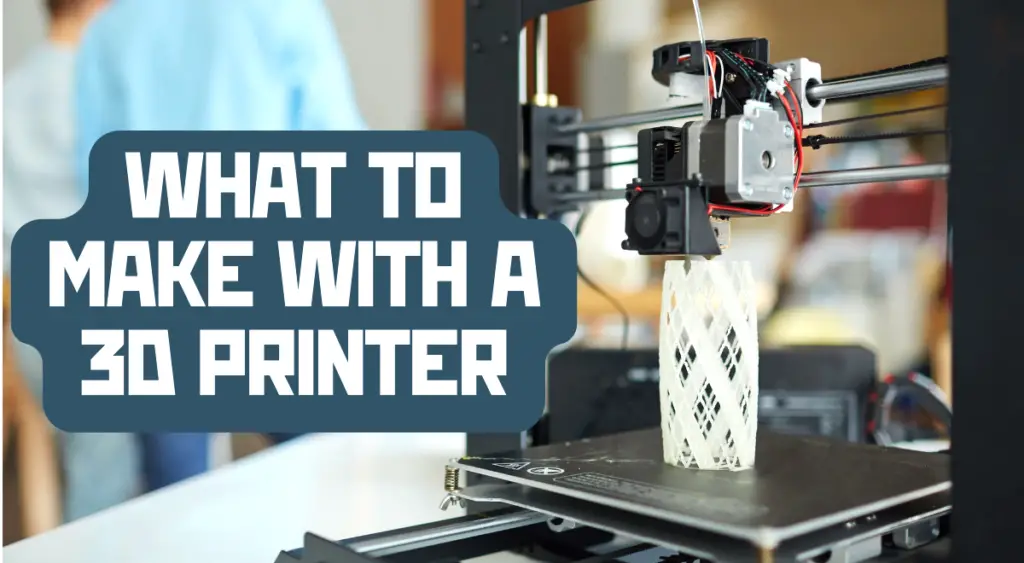

3D printers can revolutionize the way robots interact with the world by enabling them to have a softer touch. Traditional robots often have rigid components, which can be limiting in tasks that require interaction with delicate objects or humans. However, with advancements in 3D printing technology, it’s now possible to create robots with soft and flexible parts.

One approach involves printing with materials like silicone or flexible plastics, which can mimic the characteristics of human skin or soft tissues. These materials can be customized to vary in flexibility, allowing robots to adjust their grip or pressure based on the task at hand.

Another technique is to utilize a combination of rigid and soft materials in a single print. This allows for the creation of complex structures with both strength and flexibility, similar to how bones and muscles work together in the human body.

Additionally, 3D printing enables the creation of intricate designs and textures that can enhance the tactile sensitivity of robot fingertips or grippers. By replicating the patterns found in human fingerprints or adding sensory features, robots can better perceive and manipulate objects with precision.

Overall, 3D printing opens up exciting possibilities for designing robots that can interact with the world in a softer and more versatile manner. This advancement could lead to safer and more efficient human-robot collaboration in various fields, from healthcare to manufacturing.